The Technologist

A new occupational category can both create opportunities for workers and position the United States to lead in advanced manufacturing.

Soon after completing a master’s program in advanced manufacturing and design, Neha was hired as a process engineer at a semiconductor wafer-cutting plant. Not long after starting, she realized multiple processes at the plant were inefficient and out of control, but she could not solve all the issues simultaneously without the help of the other workers. She began meeting with operators and technicians from across the plant during coffee breaks to teach the process-level principles she had learned in her master’s program. By working with the operators to implement changes, she was able to get multiple processes at the plant back on track.

A few years later, Neha was hired as the production supervisor of two interconnected nanoparticle factories in New England. Again, she quickly recognized a significant quality problem spanning both plants, which could only be solved by running complex production-scale experiments. And again, she realized resolution would require buy-in from the operators and technicians. Over the course of several months, she built trust, rapport, and understanding around systems-level operations, variation, and flow among the workers in both plants. Their mutual learning paved the way for plant-wide experiments that eventually resolved the quality issue and yielded significant improvements for her business.

At first glance, this is a story of Neha’s ingenuity and persistence. But at a deeper level it exposes a problematic gap in the US manufacturing workforce. Engineers, who are expected to know systems and processes, are generally separated from operators, who are often only trained on specific machines. New manufacturing technologies, whether in robotics or digital production, are beginning to transform factory floors, requiring more workers to bridge this gap. Advanced manufacturing requires workers with a technician’s practical know-how and an engineer’s comprehension of processes and systems. Companies that want to move into advanced manufacturing often struggle to find people on the ground who know how to integrate technologies to optimize the whole system, manage technological advances, and drive innovation. Workers who have these mixed skills are hard to find.

We call this new type of worker the “technologist.” As advanced technological manufacturing progresses, technologists will be essential in the adoption of next-generation factory systems. We believe that training programs for technologists can empower both incumbent and aspiring workers to be knowledgeable, productive, and adaptable contributors to a more robust US manufacturing economy.

Training programs for technologists can empower both incumbent and aspiring workers to be knowledgeable, productive, and adaptable contributors to a more robust US manufacturing economy.

The need for technologists has been created in part by the deep disconnect between manufacturing and workforce development in the United States. For decades, US companies have sought gains in productivity by investing in capital equipment over labor. But when capital goods are globalized, so are the productivity gains, resulting in a much shorter-term competitive advantage. Alternatively, Germany prioritizes investment in the development of human capital for manufacturing through a robust system for workforce education, training, and apprenticeship. Notably, German manufacturers pay employees about 60% more than US companies. These investments have given Germany a distinct competitive advantage. The United Nations Industrial Development Organization has ranked the country as having the world’s most competitive manufacturing sector each year since 2001.

Although worker training is a reliable way to effect productivity change, the United States has historically underinvested in workforce education. Schools nationwide lack robust vocational tracks—education reforms starting in the 1970s required more college-prep courses for high school graduation and hollowed out funding for technical education—so few high school students are ready to transition to jobs in advanced manufacturing. Community colleges are too often underfunded, have low completion rates, and lack programs in advanced manufacturing technologies. As a result, innovative companies struggle to build and maintain a qualified workforce.

Without a systemic approach to workforce education, companies’ expectations for worker qualifications can be inconsistent. While developing our ideas about technologists, we talked to scores of industry executives who said they wish their technicians had more analytical skills and their engineers had more shop-floor skills. Studies have found that companies increasingly want their technicians to have the problem-solving skills of engineers—who might be less likely to visit the shop floor.

Traditional manufacturing training, which continues to be equipment-focused, does not nurture such skillsets. Companies and manufacturing education programs tend to train operators and technicians for specific machines, such as those for computer numerical control machining, welding, or injection molding. In prior eras of manufacturing, the hands-on skills this type of machine-specific training imparted could last a career. Today, however, workers need to understand the “why” of operations. As the pace of technology development and implementation accelerates, conventionally trained workers struggle to keep pace. Technicians that lack an understanding of systems-level processes are less able to engage in problem-solving and innovative thinking or to pick up new skills as processes evolve.

For many such technicians, there is no system in place for the kind of upskilling needed to assume more adaptive roles. Though shop floors are rich with opportunities to improve processes, quality, and design, technicians are rarely encouraged or taught to build the skills required to inform such changes. This is why Neha’s experience stands out. We have heard from workforce boards that companies try to promote their strongest technicians to lead teams in order to adopt or optimize new processes; however, those technicians often fumble without sufficient training in how to recognize what process-level changes might increase productivity.

In view of the failures in the current workforce training system and the large gap between technicians and engineers, we believe that new types of education to train and support technologists should be encouraged. Creating the position of technologist within the workforce can not only improve advanced manufacturing and boost industry productivity—it could also create a category of workers with more satisfying and resilient careers.

Training technologists

The integration of systems-based technologies into advanced manufacturing processes requires reconsidering the division of labor in manufacturing, and correspondingly reevaluating the skills and concepts necessary for workers at different levels.

The Massachusetts Institute of Technology first tackled the development of an educational framework for a one-year master’s degree of engineering for advanced manufacturing and design 20 years ago. The program is intended to train manufacturing engineers and eventual plant managers or entrepreneurs in automotive factories and state-of-the-art semiconductor foundries. The framework—built on years of research and manufacturers’ operational insights—is designed to teach critical-thinking skills using the four “whys” of manufacturing: the concepts of flow and variation in the (1) manufacturing processes, (2) manufacturing systems, (3) supply chains, and (4) management of people. Students begin with an introduction to foundational principles and are given opportunities to practice analyzing the fundamental building blocks that compose manufacturing. They then have hands-on experiences to apply these principles to manage manufacturing operations. By the end of the program, students are expected to know how to evaluate emerging technologies and understand how to make their company operations more agile and resilient. Recently, MIT began to broadly disseminate the core of this curriculum online through the Principles of Manufacturing MicroMasters program. The MicroMasters is aimed at engineers, product designers, and technology developers with an interest in advanced manufacturing. To date, more than 200,000 students have enrolled.

Building on the lessons learned by starting the master of engineering program and the MicroMasters, the MIT team—with support from the US Department of Defense’s Industrial Base Analysis and Sustainment (IBAS) program—is now turning its attention to adapting the curriculum to train technologists. Improved training is part of IBAS’s mission to forge more robust and efficient manufacturing capacity for the Department of Defense’s industrial base, which employs more than a million workers and includes over 56,000 companies.

Candidates for the technologist program will generally have solid factory floor experience, a community college education, or both, but there are no required credentials for enrollment. The curriculum builds on “earn and learn” approaches. Students learn hands-on knowledge of manufacturing skills using the online simulations and lab activities developed for community colleges. And as part of the program, all students participate in paid internships or apprenticeship programs to gain further hands-on experience.

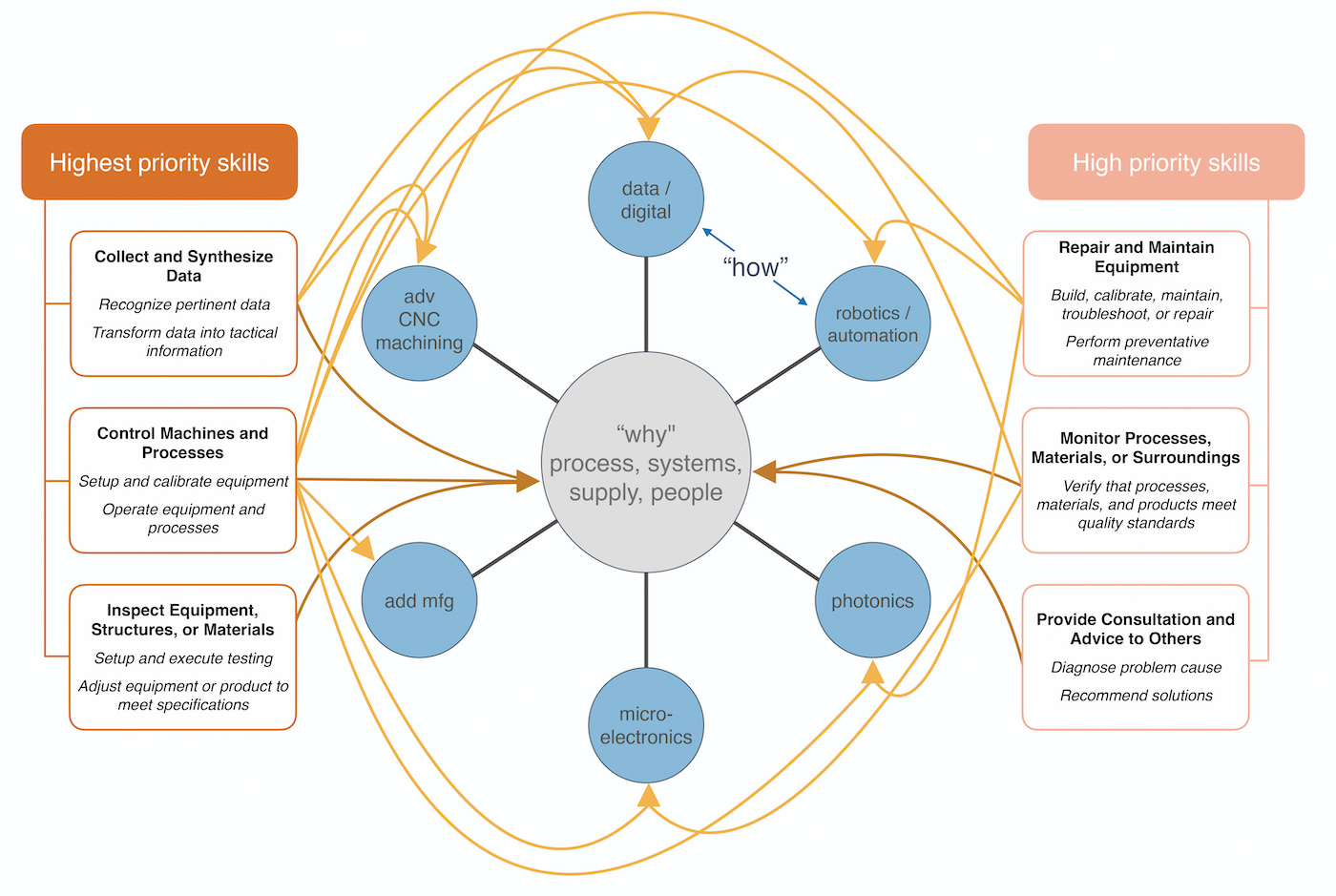

The new program is structured in a hub-and-spoke model, where the core curriculum (the hub) covers the four “whys,” and elective classes (the spokes) cover topics in advanced manufacturing such as digital production, robotics, additive manufacturing, and data analytics (see Figure 1).

The entire sequence of courses is designed to take nine months. Students who complete this intensive program earn a certificate at participating community colleges. They also earn credentials that US manufacturers across industries will recognize.

The technologist program aims to take from the best of online and in-person instruction, based on the science of how people learn. First, studies show that people learn best in bite-sized chunks, so the online content includes video segments lasting five to seven minutes broken up by assessments and feedback loops to reinforce learning and correct misunderstandings. Second, people forget what they don’t use over time, so the curriculum prompts students to periodically retrieve key pieces of knowledge. Third, people need authentic environments to try things and learn from mistakes, so the hands-on labs enable students to practice and acquire new technical competencies.

Another feature of the technologist program is its accessibility as an educational pathway. Many nontraditional students face significant barriers to education, including distance, financing, and family or work arrangements. Blending digital content with classroom sessions provides flexibility. Hands-on experience will remain vital for contextualizing theory and learning new manufacturing technologies, but conveying basic information online can cut costs and accommodate student schedules. If in-person sessions can be scheduled on weeknights or weekends, students can keep their jobs and take classes when their schedules allow. Regional partners and community colleges can support students on the in-person side by offering free or low-cost services such as childcare and transportation and by offering mentorship support to help keep students on track to complete the program.

Creating the position of technologist within the workforce can not only improve advanced manufacturing and boost industry productivity—it could also create a category of workers with more satisfying and resilient careers.

It is important also to consider affordability at the institutional level. Curriculum specialists can limit costs by developing courses once so that many students can access content. Institutions can reduce the cost of hiring expert instructors—instead, instructors to facilitate in-person labs and discussion sessions can be partial substitutes. The lab component may require schools to purchase materials and equipment to augment makerspaces, machine shops, and fabrication labs, which can cost millions of dollars. Where costs are prohibitive, virtual reality simulations can provide training for in-demand skills. For industry, since the online content is modular, courses can be used and reused without needing to constantly develop new content.

Most importantly, the technologist program has the potential to create a career advancement pathway for manufacturing workers. Prepared with a foundational understanding of how manufacturers approach production in the digital age, a worker with the technologist certification might be able to progress from technician to technologist, with a new range of responsibilities, and then with further education and experience, to engineer. Graduates of the program would be able to take on engineering tasks, qualifying them for substantial raises. Together, the curriculum and job redefinition could help break manufacturing out of its recent history of wage stagnation by creating significant new economic value and productivity advances for employers and employees.

Creating opportunity through partnership

The pilot technologist program has brought together community colleges, area employers, workforce boards, and regional universities. Similar partnerships and collaborations between sectors will be necessary to sustain the development of the technologist occupation—as well as its benefits for industry—across the country.

Community colleges are central partners in the effort to build the advanced manufacturing workforce. These schools can form vital connections between state and local governments, universities, industry, and a region’s workforce. To best leverage the nation’s community college resources to advance the technologist occupation, reforms that prioritize the goals of applicability, accessibility, and certification should be adopted across more schools. The first step is to fill the need for more community college courses and degrees qualifying new students to work in cutting-edge manufacturing fields overall. Second, more programs must be created for incumbent workers to earn certificates that qualify them for higher-skilled jobs. To accommodate the schedules and personal situations of these workers, programs should be short and skills-oriented, with certifications for each stage of skill completion. And third, courses and programs should adopt measures and tools that keep students on track with coursework. Program completion should be the goal for workers and institutions alike.

Community colleges are central partners in the effort to build the advanced manufacturing workforce. These schools can form vital connections between state and local governments, universities, industry, and a region’s workforce.

Manufacturing is inherently tied to regional economies and actors. Community college curricula, therefore, need to tie into local workforce needs. In our program, community colleges in Massachusetts, Rhode Island, and Connecticut are advising on curricula so that students will be able to earn jobs as technologists in regional manufacturing industries, such as submarine production, electronics, and medical devices. Area workforce boards and government partners help coordinate resources, advertise programs, and recruit students. Importantly, participating companies have pledged to hire entering technologists at a wage more than 30% higher than many entry-level operators in the region. This New England example can be replicated in other regions, serving as a model for industry-community college partnerships throughout the United States.

We’ve found that industry partnerships work best with groups of employers. Community colleges partnering with a single company or industry often struggle due to the fact that a company’s level of engagement may rise or fall depending on the business climate and need for workers. But to survive, community college programs need a steady flow of students. Working with groups of employers tends to mitigate the ebb and flow of individual company needs. If groups of employers and colleges work together, it’s possible to train workers who are able to assume new roles in different kinds of jobs. State and local governments should encourage these kinds of collaborations.

Community colleges working with industry have already been important partners in establishing educational programs to move students from technicians to technologists. A group of these colleges are already well-positioned to educate new technologists in the United States because of their future-oriented approaches to educating technicians. Students completing programs like those highlighted below would be exceptional candidates to pursue further training as technologists.

Lorain County Community College (LCCC) in Cleveland, Ohio has developed a group of certificate programs in advanced manufacturing skills including industrial robotics, data analytics, digital fabrication, cyber and information security, microelectronics manufacturing, manufacturing engineering, and automation systems. The certificates can stack into associate degrees and applied bachelor’s degrees. LCCC offers learn-and-earn options where students work at area companies while taking courses. Community college mentors coordinate company and school programs, providing support for students and helping place them in appropriate new jobs. Because of the effectiveness of these programs, LCCC was named the top community college in the country for excellence in student success by the American Association of Community Colleges.

Monroe Community College in Rochester, New York, offers accelerated programs in advanced manufacturing. Students move through the intensive program together as a cohort, working from 6:30 a.m. to 2:30 p.m. at partner employers and taking classes in the afternoons and evenings. Program administrators find this cohort approach fosters a supportive environment among the students and can help lower attrition rates. The program in advanced machining lasts 22 weeks and takes advantage of a new advanced equipment center, where companies as well as students can try out new technologies. The school has worked with area industry partners to develop advanced manufacturing curricula and uses a “guided pathways” approach where students plan and complete courses aligned to their own career and skill roadmaps.

With 44 full and satellite campuses throughout the state, Ivy Tech Community College is the sole community college in Indiana. It has developed a unified curriculum in manufacturing across all its campuses, which helps employers understand the schools’ degrees and certificates—and thus graduates’ qualifications. Individual campuses have flexibility to tailor part of their program to particular employers’ needs. Because Indiana is home to many production industries, there is an especially robust need for advanced manufacturing skills. Ivy Tech consequently built new elements into both its short and long manufacturing technician programs to train students to work in areas such as logic control, computer-aided design, automation, mechatronics, and robotics. It recently added systems integration and data analytics programs.

Examples such as these show that the potential to create skilled technologists exists in many parts of the country—but there is a problem of scale. The US manufacturing economy produces $1.6 trillion in exported goods annually, but federal investment in manufacturing programs across agencies is in the hundreds of millions. Federal support at the Department of Education is focused on higher ed rather than workforce education. The Department of Labor’s workforce programs are underfunded, don’t reach incumbent workers, and don’t promote advanced manufacturing skills. The National Science Foundation’s Advanced Technological Education program, the National Institute of Standards and Technology’s Manufacturing Extension Partnership, and the 16 Manufacturing USA institutes support integral efforts to develop curriculum and partnerships for advanced manufacturing education and training but have limited support. Expanding and reforming all these programs to strengthen the connective tissue across the workforce education system can create more opportunities for meaningful employment earlier in students’ careers and form the foundations for developing the new technologist workforce.

Technologists and revitalized manufacturing

American manufacturing jobs once promised economic security and mobility to the middle class. But the erosion of union power and intensified global competition have stagnated manufacturing wages. Decades of shifting production overseas has shrunk the US share of global manufacturing to only 17% compared to China’s 30%—over the past 25 years the countries have traded places in the rankings. The United States lost a third of its manufacturing workforce between 2000 and 2010 as its output share fell.

If groups of employers and colleges work together, it’s possible to train workers who are able to assume new roles in different kinds of jobs.

With a ready workforce, advanced manufacturing can help the United States regain this ground. But there is much to do to get this workforce in place. At the firm level, manufacturers are increasingly desperate for an educated and motivated workforce. Meanwhile, workers without university degrees—the largest base in the manufacturing workforce—continue to face educational barriers and career dead ends. Until this is fixed, US manufacturing will be stuck in a low-tech, low-skill rut.

Creating the new worker category of technologist can bridge the gap between labor demand and stymied human capital. A systematic effort to train technologists can create an empowered and resilient workforce, new pathways for more equitable careers in advanced manufacturing, and re-energized factory floors across the United States.

But a revitalized manufacturing sector cannot be realized without systemic investment in manufacturing labor. To incentivize and enable workers to pursue educational advances in manufacturing, companies need to offer high-wage jobs to employees. A starting technologist wage will be lower compared to what workers with university degrees in technical fields can expect—but it is still a major bump from typical entry-level technician earnings. All of this is a reminder that healthy economies are bolstered by both innovation and production, and investing in American technologists is an important first step to restoring American manufacturing competitiveness.