Will Robotic Trucks Be “Sweatshops on Wheels”?

The future of self-driving trucks is being shaped by today’s policy debates on safety, minimum wage, and truckers’—not trucks’—autonomy.

When Americans talk about automation, they tend to ask first how many jobs are at risk, or more broadly, how many jobs will there be, who will do them, and where will they be located. These are the wrong questions. They suggest a policy discussion that starts at the end, focused on mitigating negative impacts. This approach perpetuates a flawed view of how technology develops—one that plagues contemporary debates about the future of work—because it presents technological progress as a process of scientists and engineers applying knowledge and technique to the material world to find a single best way to perform some task. In short, this view of automation sees the consequences of technology for workers (job loss, lower wages, need for retraining, and the like) as largely inevitable. Nothing could be further from the truth: how a technology develops and the jobs that are destroyed or created are very much up to the public to decide.

Because current discussions are dominated by this sense of technological inevitability, people generally feel limited in their ability to make choices about the design of automation. As a consequence, the role of policy in technology development generally boils down to three approaches: first, speed it up through funding, tax law, and organizational support (think Manhattan Project for X, or funding of basic science); second, prohibit it; and third, stay out of the way and then fix problems on the backside once it’s run its course. These options leave little or no role for democratic debate and policy to shape how technologies develop and maximize the benefits of the public dollars that underlie much technological progress.

A good place to see this dynamic at work is in the emerging field of driverless trucking and automation. Today, the question dominating the discussion is, how many truckers will lose their jobs to self-driving trucks? But in reality, it is public policies that will determine what kind of self-driving trucks take to the roads. The right question to ask is, what policies will maximize the benefits of self-driving trucks to workers, communities, and the environment while mitigating costs for them? Already, the key policy questions that will decide what kind of trucks will rule the road are being debated in legislatures and the courts—they just have not been explicitly linked to automation. It’s time they were.

The key policy questions that will decide what kind of trucks will rule the road are being debated in legislatures and the courts—they just have not been explicitly linked to automation. It’s time they were.

The questions that should shape the future of trucking are not simply about how technology can increase productivity and reduce shipping costs and time; they are about the lives and compensation of human truckers, road infrastructure, and trucking’s environmental impacts. Policy in all these areas will shape how self-driving technology develops. Most immediately, these include existing policies about how truckers’ work time is counted to promote safety; whether truckers are entitled to minimum wage for all the time they are required to be at work when they aren’t driving; and what level of autonomy qualifies a trucker as an independent contractor (rather than an employee). Debates in these areas are neither speculative nor academic, and policy changes will result in very different paths of development for self-driving trucks—each with its own implications for workers, the public, and the environment. Whether the nation develops a type of trucking that results in good jobs for truckers and benefits for communities, or one that does not, depends on how society resolves debates arising from how deregulation and technology have already affected the quality and pay of truckers’ jobs.

Turning good jobs into bad ones

In order to imagine the possible futures of self-driving trucks, we first have to consider the history of truckers’ work. Because trucks move almost all the goods in the economy at some point, the work and jobs of truckers vary a lot. Some truckers deliver in a single city, perform lots of nondriving work, and spend every night at home. Others spend weeks or months crisscrossing the country driving hundreds of miles per day. Some truckers pull simple box trailers that can haul anything that can go in a box or on a pallet, while others haul specialized trailers that carry just a single product. Some own their trucks; others do not.

Not every variety of truck will become self-driving. Tankers delivering gasoline, for instance, travel relatively few miles in a day, but need to be carefully loaded and unloaded, and will likely never be driverless. By contrast, trucks that carry freight over long distances—including the so-called truckload segment of the industry—are more likely to adopt automation, at least in part because of previous policy decisions. Truckload drivers average between 400 and 500 miles from origin to destination on their trips. There are roughly 200,000 drivers who do this work.

Truckload drivers drive long uninterrupted stretches on interstate highways. The vast majority of their pay is based on the number of miles they drive or loads they complete in a week. They spend weeks or months moving across wide swaths of the country, often picking up and delivering to dozens of locations. They sleep in their trucks, taking care of their personal needs and getting most of their services at truck stops. They spend tremendous numbers of hours working, much of it unpaid, while they are waiting to pick up or deliver. In some weeks, inexperienced drivers (who are paid at lower rates) and independent contractors doing this work may not even make minimum wage.

Truckload work grew rapidly after the Carter administration deregulated trucking in 1980, setting in motion fundamental changes in the industry. Prior to deregulation, trucking companies, known as carriers, needed licenses, known as authorities, from the Interstate Commerce Commission to haul particular goods to and from particular locations. Carriers used terminal systems to combine freight based on common origins and destinations. Most of the goods moved today by truckload carriers previously went through these terminal networks as smaller shipments. After deregulation, carriers could move anything anywhere. Intense competition, which previous regulations had limited in the name of safety, service quality, and equity, rapidly transformed long-haul trucking and retail supply chains as rates plummeted. Walmart epitomizes this shift, as it created hub-and-spoke style networks of standardized stores clustered around warehouses or distribution centers rather than trucking terminals.

This new system enabled many businesses to completely avoid working with the Teamsters Union, which had heavily influenced truckers’ pay and working conditions, as well as the introduction of new technology across the trucking industry. After deregulation, drivers’ pay steadily declined, while their working hours, time on the road, and time spent waiting and sleeping in trucks increased. Ultimately, as the economist Michael Belzer described it, long-haul trucks became “sweatshops on wheels.”

The decline of truckers’ fortunes over the past 40 years is certainly about the decline of unions and labor power as a result of deregulation. But technology has allowed employers to speed up work and recruit, train, and manage a cheap and increasingly less-skilled workforce. Communications and monitoring technologies built around satellite-linked computers—commonly referred to as Qualcomm, after the company that built the first widely used system—were essential to the intensification and deskilling of trucking.

Although deregulation meant, in theory, that any trucking company could move anything anywhere, in practice, operating profitably was much more complicated. The trick was maximizing the use of trucks, but truckload freight is always “unbalanced” in some way, as the nearest load ready is almost never available exactly when and where the truck is. The strategy carriers increasingly adopted was to assign the closest load available to a truck quickly with less concern about where it was going. When the truck arrived at its destination, the driver would then be assigned a new load somewhere, and so on, until the driver needed to be routed back to where he or she started for “hometime.” For this strategy to be profitable, drivers had to be paid by the mile—and not paid for time spent waiting or time sleeping in their trucks overnight. Truckers were soon spending extended time on the road without returning home. In other words, in order to compete, carriers shifted the inefficiencies onto drivers in the form of unpaid time and worse working conditions.

Communications and monitoring technologies built around satellite-linked computers were essential to the intensification and deskilling of trucking.

This shift was enabled and increased by technology, significantly reducing truckers’ pay and quality of life. Qualcomm systems that tracked vehicle speeds and locations, in combination with sophisticated load-planning software, increasingly allowed managers to monitor and control drivers’ work. Two-way texting allowed managers to direct drivers as they worked. Trucks equipped with automatic transmissions, which became popular among fleets over the last decade or so, have opened up the job to many workers without extensive experience. The result was that large tech-savvy firms could provide cheaper service with drivers who had just six months of experience than they could with veterans. Those firms now dominate the largest segments of the industry and are the most likely to adopt self-driving technology.

The story of how deregulation and technology turned good jobs into bad ones should be a warning as the nation considers the potential of self-driving technology.

Two roads diverging

Over the past three years I’ve discussed the development of self-driving trucks with tech developers, trucking company owners, truck drivers, venture capitalists, computer scientists, engineers, labor advocates and union officials, and academic experts, among others. From these conversations I have identified multiple automation scenarios, but two appear to be the most plausible in the foreseeable future given the state of the technology and the actual work of trucking. The first is called exit-to-exit driverless, in which self-driving trucks are driverless. The second is called autopilot, in which human drivers remain in self-driving trucks. Although these are often lumped together under the heading of self-driving trucks, the models have very different implications for truckers and the environment.

The exit-to-exit driverless scenario has received the lion’s share of attention from technologists and the media. In this scenario, an autonomous truck would cover the interstate portion of a trip because driving conditions on the highway—with no intersections, pedestrians, or bicycles—are much simpler than on local roads. Human drivers would do the complex local driving from distribution centers, production facilities, or ship or rail depots to a lot—what I call an autonomous truck port—located near an interstate exit. A human trucker or staff at the port would then supervise as an autonomous tractor coupled up to the outbound trailer, performing a safety inspection and fueling the vehicle before it set off on the interstate to the next autonomous truck port.

Communities and even some truckers could benefit from such an operation. Major cities could reduce rush hour traffic congestion by putting a network of trucking ports on their outskirts, allowing local drivers to pick up and deliver loads to the port at off-peak times. This scenario could also reduce air pollution and greenhouse gas emissions because long-haul self-driving trucks would have gearing, horsepower, tires, and aerodynamics optimized for high speed and would operate in streamlined platoons. Local human-driven trucks could be electric to improve efficiency, as well as being lighter in weight to protect surface pavements and equipped with visibility features to improve safety. Together these changes could dramatically reduce fuel use, which accounts for roughly a third of all trucking costs. This model would also use drivers’ time more efficiently, and allow them to spend more time working close to their homes.

But these improvements come with additional costs. Transferring trailers from self-driving trucks to human-driven trucks will require space, labor, time, and coordination. A load that used to go directly from point to point with just two stops (origin and destination) would now make two intermediate stops, where they would need to be inspected, coupled, and uncoupled. Instead of one truck and one driver and one carrier, there would need to be three trucks, two drivers, and as many as three carriers. Most importantly, rural long-haul truck drivers could lose driving opportunities as driving jobs concentrate around cities.

In order to compete, carriers shifted the inefficiencies onto drivers in the form of unpaid time and worse working conditions.

On the whole, many of the benefits of this scenario would accrue to the public, though the costs would at least immediately be borne by the trucking carriers and their customers. Public policy that invests in the infrastructure for such a system or rewards carriers for using it, such as tax incentives for electric vehicles or reducing traffic congestion, could offset some of the carriers’ costs. But if public policy does not require or incentivize these changes, trucking carriers will choose a cheaper system that externalizes costs onto the public, truckers, and the environment.

Without deliberate policies, the cheaper option will be autopilot, the hybrid scenario that keeps a driver in the truck at all times. Autopilot could defy fantasies of shiny technology creating upskilled jobs, instead placing poorly paid humans at the beck and call of their machines around the clock. Whether human labor is cheap enough to allow use of this kind of robot truck is being decided by policy today, specifically the laws that govern hours of service for drivers, minimum wage, and employment classification.

Already, large trucking companies support autopilot as the most desirable use of autonomous trucks, often comparing it to autopilot for airplanes. When the truck is on the highway, the driver would remain in the cab, and the machine would drive itself, with the driver taking over to do local driving, fuel the truck, deal with a shipper, or handle an emergency. Promoting this scenario has many benefits for industry: human-machine driving teams could operate for far longer shifts than a single driver could without the need for additional stops at autonomous truck ports and the associated costs and risks, including the expense of different kinds of trucks, additional trailers, land for the ports, and the like. This scenario would not bring the full fuel saving of more specialized trucks—though self-driving trucks could still draft one another in platoons to achieve at least some fuel savings.

A closer look at the autopilot scenario shows the potential of today’s labor and safety policies—rather than technical capabilities—to determine the future of autonomous trucking. The autopilot scenario will further degrade the working conditions of drivers by breaking their workday into smaller amounts of local driving and nondriving work. It will also deskill the work as the machine will do the high-speed driving. These changes will strengthen the industry’s current practice of recruiting and training workers completely unfamiliar with the industry rather than raising wages to attract and retain skilled labor. Autonomous trucking, in this scenario, would be the culmination of interlocking policies that have created the structures of what truckers do and how they are compensated, which have been fought and refought since deregulation came into rule.

The central question in autonomous trucking is whether the time the truck is driving itself counts as work time for the driver, and how the driver should be compensated. That question has roots in a much longer debate about drivers’ work that started after deregulation. In the 1970s, the average trucker made the annual equivalent of over $100,000 in today’s dollars. Today, drivers at companies likely to automate make about half that much. Under regulation, the Teamsters Union negotiated a single contract with all the large employers that set the bar for wages and working conditions. As a result, there was little need for the government to intervene to ensure that truckers weren’t overworked or underpaid. Deregulation set off a series cascading changes in truckers’ work and compensation so that current rules are hotly contested and provide little certainty for the future.

Truckers’ work is covered by what are known as hours of service (HOS) regulations. HOS rules are set by the Federal Motor Carrier Safety Administration, part of the Department of Transportation. Truckers are required to record all their time as one of four different statuses (off-duty, sleeper berth, on-duty driving, on-duty not driving). Drivers cannot exceed 11 hours on-duty driving or 14 hours total on-duty in a day. They are required to take a 10-hour break. Drivers cannot exceed 60 hours of on-duty time in a seven-day period or 70 hours over eight days.

Autopilot could defy fantasies of shiny technology creating upskilled jobs, instead placing poorly paid humans at the beck and call of their machines around the clock.

HOS limits were intended to prevent fatigued driving by limiting the amount of time during which truckers have any responsibility to perform or oversee a task or wait to perform a task. Basically, if truckers are performing tasks such as driving, loading, or waiting, they are supposed to log the time as on-duty. The only time not considered on-duty is when drivers are resting in the truck in the sleeper berth, with no responsibilities at all, or when they are away from the truck pursuing their own interests. The big question for self-driving trucks will be whether the time the truck is driving itself will count as on-duty time for the driver. If HOS rules state that human drivers are on-duty even when the computer is driving, which might be prudent because of safety concerns, the autopilot scenario will most likely be prohibitively expensive for trucking companies.

But technology has already changed HOS reporting without maximizing safety benefits to the public. As of April 2019, truckers must record their hours of service using electronic logbooks that start recording “driving time” when the truck reaches a certain speed. But recording nondriving time, such as time loading at customer locations, is still controlled by drivers. Because they aren’t usually paid for that waiting time, drivers typically underreport it to allow more driving—leading most truckload drivers to exceed 60 hours over seven days, with many working 90 or more hours a week. (Geofencing customer locations to automatically record this time would have solved this problem.)

The question of how truckers should be compensated has now moved to the courts, as a number of large minimum-wage class action lawsuits have been launched against truckload carriers. Trucking companies have argued that the time workers report as on-duty for HOS is all they are entitled to be paid for. But the Department of Labor, which governs minimum wage, uses a broader definition of work, including, potentially, all the time a worker spends for the benefit of the employer. This definition would include almost all the time a trucker is required to spend on the road (other than sleeping time) in order to do the job.

Using the Department of Labor’s rules, many drivers do not earn minimum wage every week. Independent contractors’ expenses frequently exceed their revenues, even when they are working five days a week. Trainees may drive thousands of miles for as little as $350 a week. Even moderately experienced drivers can sit unpaid for days and fail to earn minimum wage as a result.

In October 2018, a US District Court in Arkansas ruled that long-haul drivers were entitled to at least 16 hours a day of minimum wage, explaining that although HOS rules are intended to ensure safety, they do not determine compensability. For nearly six decades, the Department of Labor has consistently stated that drivers are working if they are “engaged to wait,” meaning that if the waiting time they endure is an integral part of the labor process, they are working and the time is compensable. Since deregulation many long-haul carriers have ignored this, as did drivers, until wages dropped so low that they violated minimum wage laws.

Many drivers do not earn minimum wage every week. Independent contractors’ expenses frequently exceed their revenues, even when they are working five days a week.

That is not the end of the matter, however, as the Trump administration issued new guidance in July 2019 saying that entitling drivers to compensation for all the time required by the job other than sleep “is unnecessarily burdensome for employers” and that the “time drivers are relieved of all duties and permitted to sleep in a sleeper berth is presumptively non-working time that is not compensable.” This matter is far from settled, but if drivers are eventually found by the courts to be either working or entitled to minimum wage, this will also provide a strong disincentive for the autopilot scenario.

Yet another policy debate that will influence the future design of self-driving trucking is employment classification. Many big trucking companies currently make heavy use of independent contractors. Contractors are much cheaper than employees because they are exempt from basic benefits, including employer contributions to Social Security and Medicare, unemployment insurance, and workers’ compensation, as well as from basic labor protections, such as the right to join a union. Critics argue that this is an employee misclassification—and California in 2020 instituted a landmark law known as AB5 that establishes a legal test of employment for companies that use contractors. In the case of trucking companies, the law essentially says if you hire a trucker, that worker is your employee.

Although the trucking industry continues to claim that independent contractors are part of a long-standing tradition of owner-operators, the relationship has been transformed by satellite-linked computers and the associated management systems that allow carriers to monitor and manage drivers. Despite the fact that the truckers bear the risk and burden of paying for the trucks they drive, they are now often otherwise indistinguishable from employees as a result of these systems.

So far, technology has dramatically reduced the autonomy of truckers, and it’s likely that self-driving trucks will erode it still further, so that humans are essentially tending to the needs of the machine. Self-driving trucks might be able to drive themselves safely in most situations, but a driver may still need to take over in case of traffic, bad weather, malfunction, or crashes. Envision this situation: a self-driving truck is operating normally on an interstate, but several miles ahead a disabled vehicle is partially blocking the right lane. Road flares, debris from a blown tire, emergency personnel, or “rubber-necking” cause the self-driving system to request that the human driver take over. If there is no driver in the truck, an expensive remote piloting system might be used to “rescue” the truck with a driver operating the vehicle from a command center far away. Obviously, if there is a driver in the cab, he or she could be alerted by an alarm and hop into the driver’s seat—a much simpler, cheaper proposition—but only if policy continues to reflect the idea that such an owner-operator is an entrepreneur rather than an employee.

Technology has dramatically reduced the autonomy of truckers, and it’s likely that self-driving trucks will erode it still further, so that humans are essentially tending to the needs of the machine.

Thus, the feasibility of the autopilot model rests on how the drivers are paid, and what sort of “work” regulators see them as doing. A straightforward interpretation of HOS rules would suggest that all the time a driver spends in a self-driving truck should be logged as on-duty, which would entitle the driver to pay. But even if a driver is fully relieved of all responsibility for operating the truck on the highway, should his or her time in the sleeper berth while the truck operates itself be considered “sleeping” for HOS? Can drivers get adequate rest while the truck is driving itself? Although there are team drivers today who operate with one person driving while the other is off-duty, these teams are often family members or couples—it takes no small amount of trust to sleep in the back of a big rig as your driving partner logs long hours behind the wheel, especially at night. No one yet knows whether it will be easier or harder to get adequate sleep with a machine driving, and answering this question will take years of research in real-world conditions. In addition, because much of the freight currently being hauled by truckload carriers does not travel a full 10 hours, drivers might not get a full break as the rules currently require, potentially producing a nightmare scenario in which drivers are working random hours for weeks or months at a time. If government cannot quickly figure out how to manage the issues of trucker compensation, the nation could easily end up with a model of autonomous trucking where humans are simply poorly paid attendants to robots, working in cramped and lonely conditions, with little sleep, and few prospects.

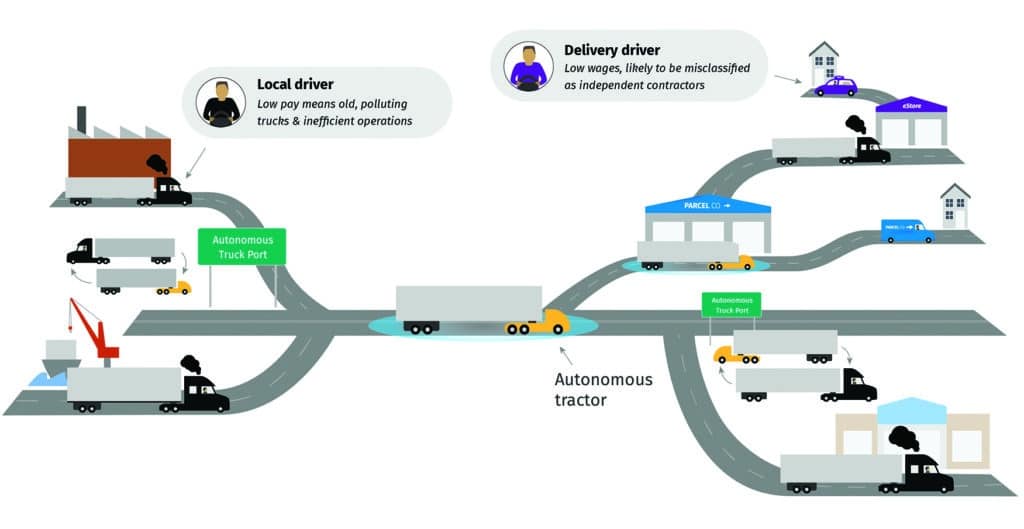

Figure 1: Most likely automation scenario, absent policy intervention

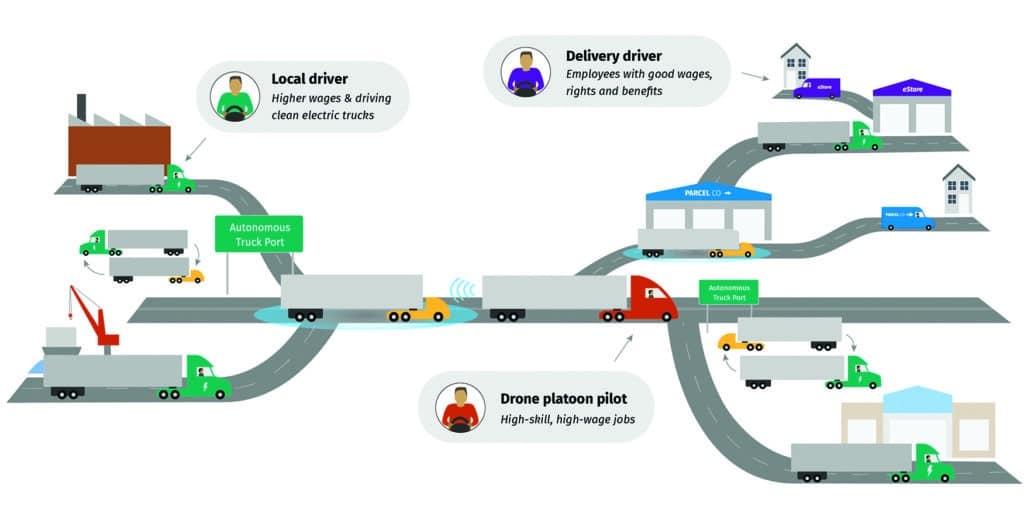

Figure 2: Alternative automation scenario, with policy intervention

Changing the rules of the road

Technology alone cannot bring about a clean, safe, high-skill, high-wage, trucking industry. Instead, government policies being debated now—on vehicle standards, communications, taxation, energy, insurance, infrastructure investment, and funding, among others—will critically influence what kind and how many self-driving trucks are on the road, and what kind of income and working conditions drivers will have. It is time for the public, and truckers themselves, to become more involved in these deliberations, which will also shape the price and quality of freight transportation, the safety of roads and infrastructure, and the amount of climate-changing carbon emissions linked to the trucking industry.

The nation could easily end up with a model of autonomous trucking where humans are simply poorly paid attendants to robots, working in cramped and lonely conditions, with little sleep, and few prospects.

The stakes are high, and the benefits to the public are potentially great—but so are the risks. If self-driving trucks can cut the cost of freight movement by truck by a third or more, as some analysts have suggested, it will become the preferred method of transport for even more freight, shifting freight now shipped by rail to trucks. But such a shift would jeopardize efforts to reduce total carbon emissions, because trains hauling freight are far more fuel efficient than trucks. And further policies will be required to protect the vulnerable communities surrounding freight corridors, which already suffer egregiously high rates of asthma and other health consequences of diesel pollution.

The nation is at a transformative moment in moving goods. Not only do electric vehicles and automation offer the possibility of drastically reducing emissions and pollution from moving freight, diverse technologies are enabling a dramatically different twenty-first century freight system. E-commerce has triggered a shift in purchasing away from big box stores toward home delivery—and COVID-19 is speeding up this change. In such a pivotal moment, the nation needs to focus on how the benefits and costs of the trucking system are split up. Who will pay? When it comes to robot trucks, will we choose a low road or a high road?